Medium Duty Wheel Balancing – Balancing a 2012 Chevy Silverado Wheel (8 x 180)

Despite being one of the most critical aspects of wheel balancing, properly mounting wheels on balancers is all too often undervalued or completely dismissed as a requirement to the wheel balancing process. The biggest factor contributing to this is balancer OEMs design, promote and sell balancers…not mounting equipment…adaptors are not part of their core competency. Cones are the least expensive and most basic option for mounting wheels on balancers and require no training on the part of the OEM. As a result, training and education is spent on operating the balancer with little or no time spent on mounting equipment and its importance to wheel balancing. But here’s the problem with that…

Balancing begins with centering.

Balancers do not center…adapters do. Without the right adapters, used in the right way, wheels are not centered meaning a zero on the balancer doesn’t necessarily mean the wheel is balanced. Weight can be added and removed and added again until you get zeroes but then what about repeatability? And why are there more and more wheels that balancers just can’t balance? For balancers to do what they are intended to do, wheels must be centered and mounted on the balancer exactly as they are on the vehicle. In today’s marketplace, it is important to consider both hub centering and lug centering on every wheel so that wheels are always mounted correctly on the balancer. Not only will this optimize the balancers ability to balance but also allows shops to provide truly balanced wheels to their customers. Mount wheels properly, and vibrations, chasing weights, false zeroes and comebacks become a thing of the past.

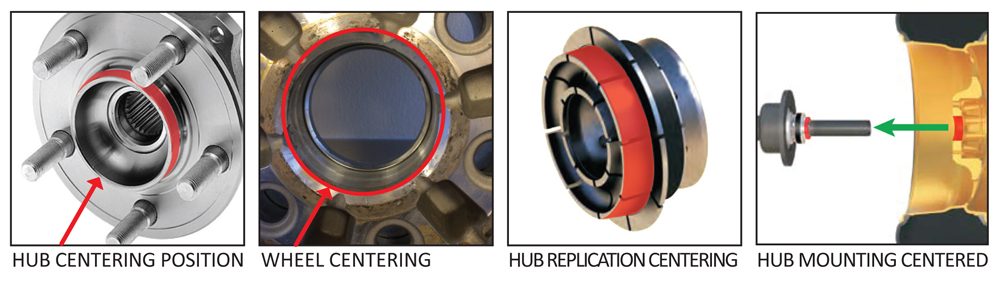

Centering on the Balancer

Hub Centering

Balancing begins with centering…and centering (for most wheels) begins at the hub. Centering on the vehicle happens when there is 100% contact with the machined track on the inside of the wheel hub and the hub assembly flange, or in simpler terms, when the wheel is connected to the axle hub. See red markings on wheel hub and hub assembly below for detail.

Consider this…

- There is no taper on hub flange for centering (problem with cones used back or front).

- The hub flange does not mount to the front of the wheel hub opening (no front coning).

- Duo Expert offers 100% contact to the machined wheel hub track for zero tolerance centering.

- Always place hub centering devices on the shaft first before mounting the wheel to mimic mounting on hub assembly flange.

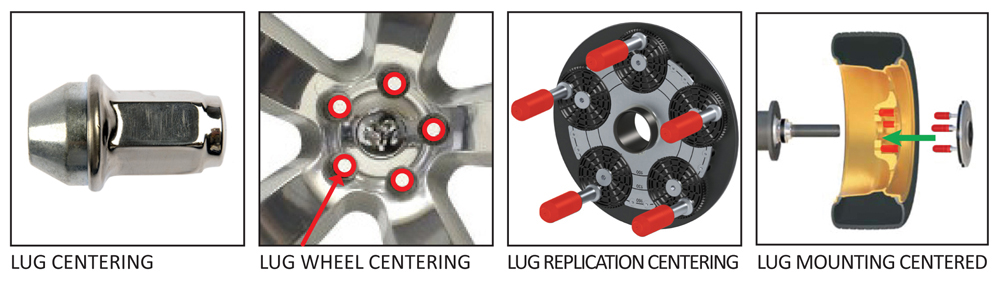

Lug Centering

Balancing begins with centering and centering is either reinforced through lugs or the actual centering point for truly lug centric wheels (aftermarket wheels) where the wheel is centered by the lugs rather than the hub. With either Quick Plates or Flange Plates, the lug mount on the vehicle is replicated exactly on the balancer and provides the same resistance to side to side movement pushing the wheel away from the centered mount.

Consider this…

- Pressure cups provide pressure from the front of the wheel on balancers but have nothing to do with lug mounting or replicating the vehicle’s lug mount and often do not contact wheels in the proper location.

- Pressure cups, ironically, do not provide even pressure/torque which is required from lug mounting.

- Quick Plates and Flange Plates provide even pressure and enough torque to push the wheel into its proper mounting position on the hub centering device.

- When balancing aftermarket wheels, always use the tuner style tips or studs for proper centering.

That’s why you can’t have one without the other…proper hub and lug centering devices. Adapters complete balancers. They are every bit as important as the balancer itself.

Market Conditions Affecting Wheel Balancing:

- Standard Tooling

- Front Coning

- Chrome Clad Wheels

- Wheel Dynamics – Heavier and Larger Wheels

- More Sophisticated Vehicles

- Aftermarket Wheels

- Alloy Wheels

- 8 and 10 Lug Vehicles in the Fleet

- Balancing – Speed More Important than Accuracy

- Tech Training and Supervision – Not Enough Time Invested

The Front Coning Issue

Over 70% of wheel balance comebacks can be directly attributed to the way wheels are mounted on the balancer. The single biggest contributor to mounting problems is using a cone from the front of the wheel or front coning. The contact point on the cone has nothing to do with the way the wheel is mounted on the vehicle. A front coned wheel on a balancer cannot be accurately or properly balanced.

Over 70% of wheel balance comebacks can be directly attributed to the way wheels are mounted on the balancer. The single biggest contributor to mounting problems is using a cone from the front of the wheel or front coning. The contact point on the cone has nothing to do with the way the wheel is mounted on the vehicle. A front coned wheel on a balancer cannot be accurately or properly balanced.

Unfortunately, front coning has become standard practice in many North American shops as it speeds up the balancing process and requires little or no training. Consequently, it has arguably become the most serious problem in wheel balancing today. As long as front coning is allowed and accepted in shops, wheel balancing cannot be taken seriously. Front coning is a practice that has to be educated out of the marketplace and eliminated from all shops. Professional shops that take the time to properly educate/train their techs and place importance on balancing wheels precisely and accurately are the shops that can be trusted to give their customers the tire and wheel service they deserve.

Chrome Clad Wheels

A clad wheel is a cast wheel with a chromed, plastic cover bonded to the face of the wheel. Their presence in the marketplace is growing like wildfire because auto manufacturers have realized that the same cast forgings can be used for several makes and models with the clad cover providing the difference in appearance. So, what was once primarily considered a Chrysler wheel design, is now being used on Chevy, Ford, Audi, Mercedes, Toyota and Nissan to name a few. By 2015, it is estimated that over 60% of new vehicles entering the fleet will come equipped with clad wheels.

The effect clad wheels have had on wheel balancing has been profound to say the least: in order to properly balance a clad wheel, standard cones and pressure cups cannot be used. Use of cones from the back, cones from the front and pressure cups on the surface of the wheel will not only result in inaccurate balance results but can also cause expensive damage to the wheel. Because chrome clad covers cannot be removed, repaired or replaced, it is important to understand that any damage to the cladding results in wheel replacement at the shop’s expense…and clad wheels do not come cheaply. To avoid clad wheel issues in the shop, the following details the problems and solutions for balancing chrome clad wheels:

- Clad Surface I – Because the plastic material is soft and easily scratched, there can be no surface contact on the clad cover.Pressure cups pressed to the clad surface, with or without the rubber ring, will scratch and damage the wheel requiring expensive wheel replacement.

- Clad Surface II – Many clad wheels have a pocket between the clad cover and the wheel’s casting. Pressure cups tightened against the clad cover can crack and/or cave in the plastic cover requiring expensive wheel replacement.

Clad Surface Solution – Flange plates or Haweka Quick Plates are required to prevent any surface contact with the wheel. So that a lug centering device is used on every wheel not just clads, Quick Plates are highly recommended for optimum balancing results. - Back Coning – If a standard cone is used properly from the back of a clad wheel, two problems occur:

- Balance Accuracy – The length of the cone (2 inches plus) is such that the cone’s point of contact in the wheel hub is actually the clad cover. The plastic cover is soft, moveable and has nothing to do with the way a wheel is mounted to a vehicle. It is impossible to properly balance a wheel mounted on or touching the chrome clad cover in any way. Results will always be inaccurate.

- Hub Cover Clips – Many clad wheels have plastic clips in the inner hub bore to hold the wheel’s hub cover in place. These clips are thin and very easily broken. When a cone is used from the back, the clips press against the cone and often break. This results in a loosening of the clad cover, wheel vibration and expensive wheel replacement.Back Coning Solution – Hub centering devices designed and sized to have no wheel hub interference are required for balancing clad wheels. Haweka Pro Collets (two sided, 3/4 inch length each side, low taper collets) or Duo Collets used from the back of the wheel provide clad wheel solutions. For maximum results, Duo Collets are recommended as the mounting surface replicates the vehicle’s exactly.

- Front Coning – As iterated and reiterated many times on this site, cones should never be used from the front under any circumstance. Balancing results from front coning are inaccurate and meaningless. Like back coning, there are two issues when coning from the front:

- Balance Accuracy – When a clad wheel is front cone mounted on a balancer, not only is the point of contact of the wheel completely irrelevant to the way it is mounted on the vehicle but also, because the plastic cladding covers the hub bore there is no contact whatsoever with the wheel itself. The plastic cover is soft, moveable and has nothing to do with the way a wheel is mounted to a vehicle. It is impossible to properly balance a wheel mounted on or touching the chrome clad cover in any way. Results will always be inaccurate.

- Hub Cover Clips – Many clad wheels have plastic clips in the inner hub bore to hold the wheel’s hub cover in place. These clips are thin and very easily broken. When a cone is used inaccurately from the front, the clips press against the cone and often break. This results in a loosening of the clad cover, wheel vibration and expensive wheel replacement.

Front Coning Solution – Use hub centering devices only from the proper position at the back of the wheel. Haweka Pro Collets (two sided, 3/4 inch length each side, low taper collets) or Duo Collets used from the back of the wheel provide clad wheel solutions. For maximum results, Duo Collets are recommended as the mounting surface replicates the vehicle’s exactly.